Underwater NDT Inspection

Planys conducted a routine underwater inspection of a Coal and Liquid Jetty piles in West India. The client was not interested to clean the thick marine growth on the piles (typically required for traditional NDT) due to costs and risks involved. Thus, a very sophisticated underwater corrosion monitoring NDT technique was integrated with Planys ROV Beluga to assess the condition of 75+ piles taking close to 1000+ readings across 500+ locations without marine growth cleaning.

Scope of Work: Underwater NDT of 75+ piles at a Chemical Terminal

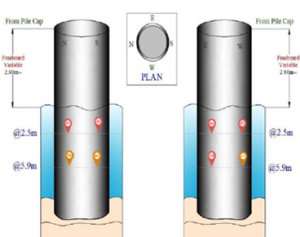

Planys Solution: The inspection was carried out by Planys’ ROV Beluga equipped with high resolution camera, advanced NDT probe, altimeter and depth sensor.

- Planys ROV Beluga was re-engineered to hold manipulator arms & integrated with an advanced NDT technique for thickness loss estimation for a steel pile.

- This technique did not require the cleaning of the marine growth and thus making the overall inspection cost effective and 3 times faster than traditional methods.

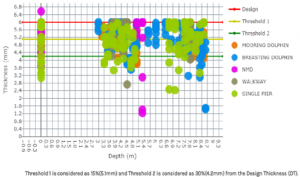

- Over 50 locations had more than 30% drop in jetty pile wall loss from design/as-built thickness, 130+ locations had between 15-30% drop while the rest were in acceptable range.

- The captured data was plotted on a point summary chart where design thickness and different thresholds were marked.

- All anomalies/defects were plotted against geo-tagged CAD drawing of every section on the Planys Analytics Dashboard (PAD) with localised click-to-view feature.

Images show deployment of the ROV system during inspection and extent of thick marine growth

Images of from ROV Camera showing NDT probe touching the marine growth, snapshot of PAD showing “Thickness data hot-spot” map and consolidated thickness summary chart