Open-Roof Storage Tank (Fire Water, Potable, DM)

Planys conducted underwater inspection for an open-roof fire water tank in an oil and gas refinery. Internal concrete lining of the tank had collapsed on the top side. The client wanted to plan the maintenance better and thus without taking a shutdown and without dewatering, they wanted to inspect the fire-water tank.

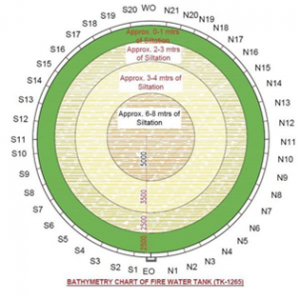

Scope of Work: The scope of work included visual inspection of a tank of diameter 20m and height 15m. The inspection aimed to identify extent of damage to the internal concrete lining. Additionally, computation of silt accumulation at the bottom was desired.

Planys Solution: The inspection was performed using Planys’ ROV Mike equipped with high resolution camera, turbid water module and depth sensor.

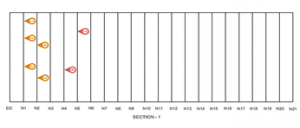

- Only 10 defects were identified on the internal lining and were categorised by severity (moderate/minor) and also by type (crack/spalling) and marked on the tank drawing.

- Since the water was from the creek nearby, Planys’ turbid water module was used along with its proprietary image enhancement software to reduce cloudiness in the videos.

- Dimensions of cracks were also extracted using LASER scaling module on Planys ROV.

- ROV Mike also assessed the silt levels & 25% of the tank was found to be filled with silt. Apart from a maintenance issue, this was also a safety issue as this tank only had 75% fire-water.

- Overall, the tank was in good condition and this helped the client inform the repair contractor to appropriately plan. It also brought down the shutdown period by 75%.

Images show deployment & setup of the ROV system and defects captured during inspection

Images show defects captured during inspection with Planys ROV & snapshot of the “defects hot-spot” map delivered to client for a certain section on Planys Analytics Dashboard (PAD)