Closed-Roof Storage Tank (Fire Water, Potable, DM)

Planys conducted underwater inspection for a closed-roof potable water storage tank inside a Petro-chemical plant. Since construction, the tank was never inspected due to other priorities during shutdowns. The client wanted to inspect the tank in online conditions (without de-watering) to pro-actively plan for the upcoming shutdown & maintenance.

Scope of Work: Underwater visual inspection of a tank shell & roof (diameter 25m and height 18m) and wall thickness measurement of tank floor/base plate in live/online (without taking shutdown or de-watering) condition.

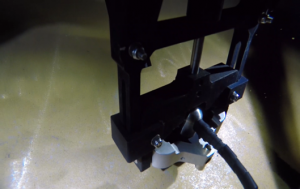

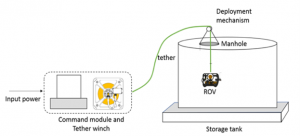

Planys Solution: The inspection was performed using Planys’ ROV Orca equipped with high resolution camera, ultrasonic thickness (UT) measurement probe mounted on a gimbal, altimeter and depth sensor.

- Deployed through the roof manhole, ROV Orca covered the shell in grid of 2m spacing.

- Gimbal mounted UT probe was placed on the belly of the ROV and collected very reliable/repeatable data for bottom plate thickness

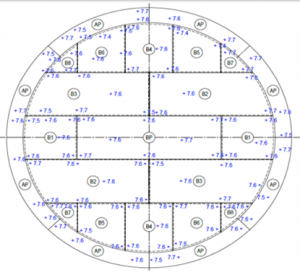

- Defects identified were categorised by severity (moderate/minor) & along with UT measurements were geo-tagged on the tank drawing visible through the Planys Analytics Dashboard (PAD).

- Overall, the tank was in pristine condition and this helped the client take a decision to completely fore-go the planned upcoming shutdown thus saving time, cost and resources.

Images show ROV deployment & setup and bottom camera feed while taking UT readings

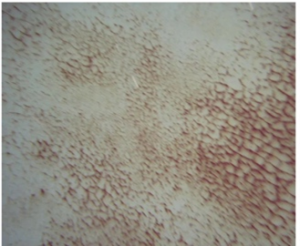

Images show minor corrosion captured on the roof, near the sump and on the shell of the tank;

Tank floor CAD drawing with UT measurements geo-tagged against position within the tank