Under Berth (dry region) Inspection

Planys conducted underwater inspection for the under-side of a berth at a port in western India. After a cyclone, 3 cranes collapsed on the berth and parts of the crane pierced the berth at different locations. Due to low clearance caused by tidal variation and berth height, it was an unsafe environment to send human divers to examine the extent of damage.

Scope of Work: Inspection of a section of the berth from the under-side (dry region) to assess the damage to the berth/deck/slab due to crane collapse. The inspection aimed to identify locations of structural defects on the under-side.

Planys Solution: The inspection was performed using Planys’ ROV Beluga equipped with high resolution camera (facing upwards), turbid water module, LASER scaler and depth sensor.

- Over 100+ major defects were found – rebar exposed, beam-bulging, cracks & spalling.

- Dimensions of the extent of defects was extracted using Planys’ unique LASER scaler.

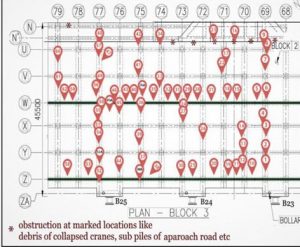

- All anomalies/defects were plotted against geo-tagged CAD drawing of every section on the Planys Analytics Dashboard (PAD) with localised click-to-view video feature. The report was given to the consultant for further action on dismantling of crane/rehabilitation of berth.

Images show deployment & setup of the ROV system and defects captured during inspection

Photo shows ROV fitted with camera, defects captured during inspection & snapshot of the

“defects hot-spot” map delivered to client on Planys Analytics Dashboard (PAD)